Supporting the circulation of non-recycled plastics by optimising recycling technologies, collection and logistics

TREASoURcE is focusing on three types of plastic waste streams that are not currently being recycled: agricultural, municipal and industrial. Mechanical and chemical recycling methods are chosen as the recycling routes towards new consistent and reliable secondary raw materials.

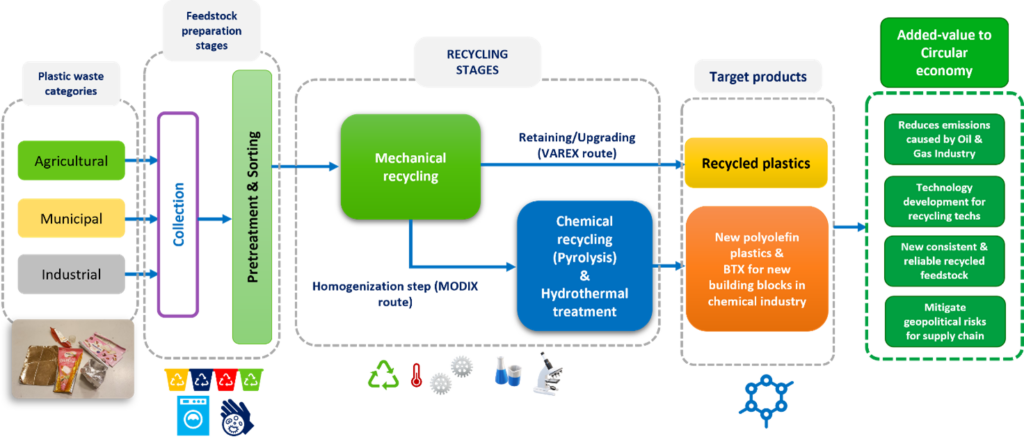

It is critical to evaluate and implement collection, pretreatment, and sorting steps before the plastic waste streams are processed with the selected recycling technology. Collection, pretreatment, and sorting steps depend on the requirement of each recycling route and the particular waste stream. Mechanical recycling demands better separation of polymer types, which is achieved by various sorting techniques. Washing and drying of plastic waste can also be applied according to the quality specification necessary for the reclaimed material and the contamination level of the plastic waste. In the figure below, an overall scheme for the TREASoURcE project’s approach is shown, starting from the collection of different plastic waste streams to pretreatment, sorting, and recycling routes towards the production of new added value plastic products.

In TREASoURcE, nine different plastic waste streams of municipal and agricultural origin from Finland and Norway have been evaluated to represent the key plastics streams on a regional and end-use basis. Their suitability for mechanical and chemical recycling techniques has been assessed by VTT and SINTEF.

Towards circular plastics

A dedicated focus was placed on the collection activities for municipal rigid plastics such as plastic items, furniture, and pipes in the Pirkanmaa region of Finland, as these items are not systematically recycled. In this context, EKOF has completed a collection campaign for hard plastics. A two-month-long campaign was organized to collect the feedstock, in cooperation with the Pirkanmaa municipal waste management company. During the campaign, citizens could bring rigid plastic waste to two waste stations in Tampere and Nokia. The composition of the collected plastics was analyzed in cooperation with Tampere University of Applied Science students. Representative samples were transferred to VTT for characterization to assess their viability in different recycling technologies.

Mechanical and chemical recycling are applied as complementary technologies in TREASoURcE. The decision on the recycling route is determined based on the suitability of each technique for the specific plastic waste stream. After the characterization of these waste streams, VTT utilizes two distinct mechanical recycling technologies. The MODIX extruder was primarily run as a pretreatment stage for mixed plastic waste before chemical recycling (pyrolysis). This process is particularly useful for plastic waste that has not been ideally sorted and separated into mono-material plastics.

The MODIX extruder facilitates the compacting and homogenization of plastic wastes and provides a consistent feed for chemical recycling which then converts the plastic waste into either solvent-based chemicals (BTX) or naphtha for a steam cracker. Catalytic pyrolysis is used for solvent production to selectively convert the plastic molecules into BTX. Chemical recycling of plastic waste into naphtha for a stream cracker, along with catalyst screening, has been tested in small scale with agricultural and municipal plastic waste at VTT. Following the selection of the optimal catalyst combination, the process will be scaled up using a bench-scale process development unit and a pilot unit. Plastic waste streams that are sorted into mono-material streams are processed using conventional extrusion.